🦄 vol. 52

claude chats about automation and labour 🤖

revolutions, robots and replacement 🤖

The notion of automation and machines replacing humans has made headlines for many years now. But with the advent of robots that operate autonomously, is this sentiment still just alarmist hype?

By definition, automation describes a set of technologies that reduce human intervention in processes. The goal of automation is achieving increased output, speed and efficiency of production.

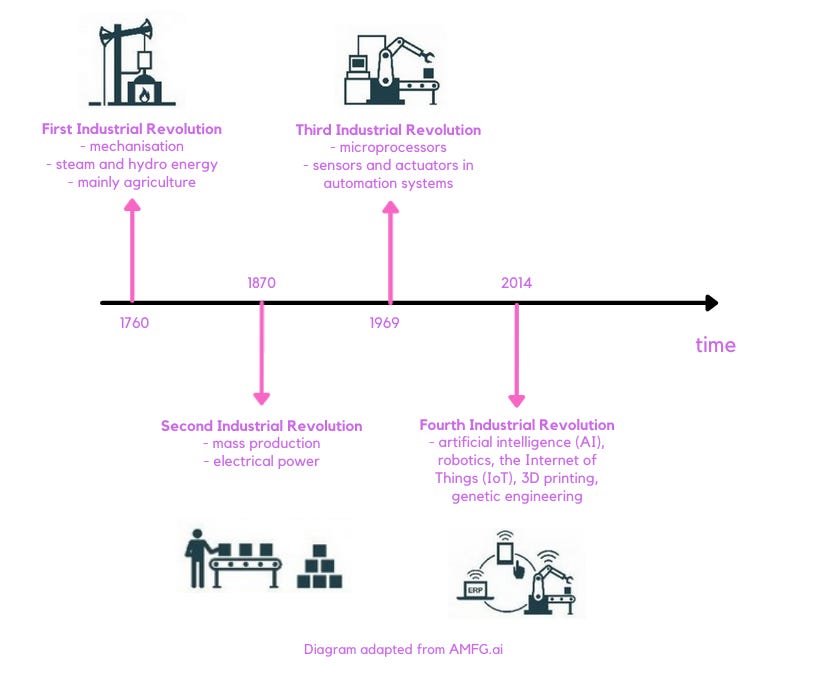

It’s also NB to note that the state of automation has seen several periods of booms throughout human history...

A timeline of industrial automation 💭

1️⃣ First industrial revolution: This came about by the use of steam power and the mechanisation of production. In 1783, Oliver Evans developed the first automatic flour mill using a series of bucket elevators to move grain from one process to the next within the mill.

Notable advances: development of the steam engine, steam ships, steam-powered locomotives.

2️⃣ Second industrial Revolution: Practical application of automation was enabled and accelerated by the proliferation of electrical power which enabled mass production on assembly lines. Henry Ford took inspiration from slaughter houses where pigs hung from conveyor belts and butchers performed only part of the butchering task and applied the same principles to automobile production.

Notable advances: lightbulb, internal combustion engine, automobile, aeroplane, telephone.

3️⃣ Third Industrial Revolution: Also dubbed the digital revolution, is characterised by the move from analogue to the digital. The introduction of memory-programmable controls and computers allowed us to fully automate an entire production process without human assistance.

Notable advances: personal computers, the internet

4️⃣ Fourth Industrial Revolution: We are currently in this phase. It is conceptualised as the application of information and communication technologies to industry. Production systems are brought online with network connections. Some advancements this is expected to bring about are

Machines which can predict failures and trigger maintenance processes autonomously.

Auto organised logistics which react to unexpected changes in production.

Throughout the various revolutions, it is clear that the trend is always towards increased levels of automation. The thought on many people’s minds is whether there will be anything left for us humans to do.

Many view the current era of automation led by artificial intelligence and industrial robots as the precursor of mass unemployment. It’s also argued that, like the revolutions before, the outcome will be a renewed increase in demand for labour. So which is it?

A framework for understanding the effects automation 🤔

MIT professor Daron Acemoglu and Boston University professor Pascual Restrepo, present a task-based framework for reasoning about the implications of technological advances on productivity and the demand for labour. The premise is:

Production requires tasks that are allocated to capital or labour.

While new technologies increase the productivity of capital and labour at tasks that they currently perform, they also impact the allocation of tasks to the factors of production (capital and labour) - they call this the task content of production.

The claim is that shifts in the task content of production can have major effects on labour demand as well as implications for productivity.

To illustrate this, take the example of a hypothetical small coffee producer:

They purchase unprocessed coffee.

They have roasting machines with which they turn unprocessed green coffee into aromatic brown beans (like the ones we purchase at the store).

Being a small producer, the roasting machines are not fed by a continuous process, but rather they employ staff to operate the machines as well as to manually package the roasted coffee beans.

The roasting machines (capital) are responsible for roasting and the staff (labour) operate the machinery and perform the packaging. This allocation of tasks forms the task content of production for the coffee maker.

The effect of automation 🚜

Building on our example above, if the coffee maker were to upgrade and purchase machinery that could handle packaging, the task content of production of the coffee maker would change due to the increased automation, some of the staff responsible for packaging might have to be applied to new tasks or become redundant. This is also known as the displacement effect.

Automation and displacement 🛫

In the late 1700s, workers reaping the fields were displaced by mechanised horse-powered reapers.

In the 19th century, assembly line workers were displaced by fully automated end-to-end production processes.

Today, a lot of white collar jobs are seeing some of the tasks they performed replaced by specialised software as well as artificial intelligence.

Acemoglu highlights that the impact of automation is not solely the displacement of existing labour. By leading to an increase in productivity - the productivity effect - it contributes to increased demand for labour for tasks that cannot be automated.

Furthermore, the displacement effect is counterbalanced by new technologies that create new tasks in which labour is effective. These tasks generate a reinstatement effect — they reinstate labour into a broader range of tasks.

Automation and reinstatement 🛬

These examples are chosen to mirror some of previous examples of displacement:

Workers could retrain to manufacture, maintain or operate the machinery used to reap.

While assembly line workers were made obsolete, new occupations opened up in the form of mechanical engineers for the machinery, control engineers for the processes, etc.

Although software has made some white collar tasks redundant, they have created more in the form of programming and maintenance of software.

What potentially makes the current industrial revolution different? 💭

The current era of automation is seeing the mass adoption of fully autonomous industrial robots that are reprogrammable, multipurpose machines capable of performing a variety of tasks.

In a recently published paper, “Robots and Jobs: Evidence from U.S. Labour Markets,” (also by Acemoglu and Restrepo) highlighted several concerning trends:

Every robot added per 1,000 workers in the U.S led to a decline in wages of 0.42% and a decrease in the employment-to-population ratio by 0.2%.

Robots affect workers across all education levels negatively, but it is the workers lacking college degrees that bear the biggest downside.

When jobs at a certain level of complexity disappear, those workers take jobs away from lower skilled workers.

Automation technologies always create both displacement and productivity effects. However the above trends imply that robots create a stronger displacement effect, therefore having a net negative impact on labour.

Where to from here? 🔭

Finding ways to counter the negative effects of automation is an active field of research. Researchers are investigating the feasibility of programs such as “Universal basic income” and “Robot taxes” as policies to be implemented in order to mitigate the effects of automation on employees whose skills are made redundant. Time will tell.

claude

claude found it interesting that netflix is exploring introducing a cheaper ad based tier

today’s piece reminded sash of his (mind-blowing) tour of the tesla factory a few years ago